KLUG archival paper and board qualities decisively improved

Folding and Grooving characteristics of KLUG archival paper and board qualities decisively improved

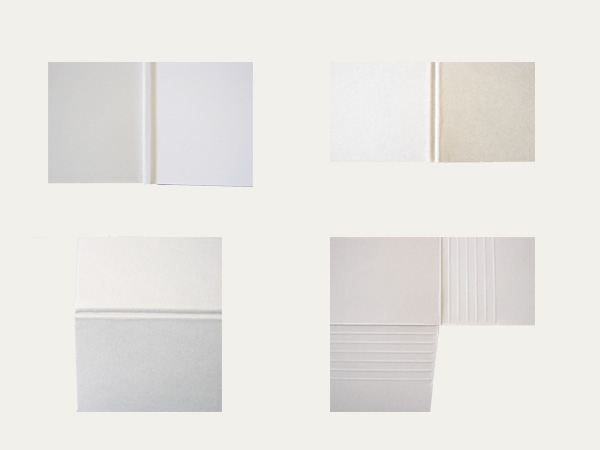

The requirement for grooving board materials has both functional and aesthetic reasons. During the grooving process the exact poistion is marked where the board is to be folded (creased). Faultlessly executed grooving definitely extends the life span of folded board materials. Whilst grooving, a typical hinge like bendable zone is created in the board material (or corrugated board). During this process the tensile strength of the material must not get reduced. Within the groove the flexural stiffness is reduced significantly, enabling easy folding, between 90° and 180° without causing any damage. The elongation of the paperboard fibres prevents cracking of the the upper surface layers. Besides a technically perfect grooving process the composition of the fibres in the paperboard is decisive. KLUG-CONSERVATION has re-engineered the fibre-mix of their archival paper and board qualities (047 and 048) in order to obtain even superior quality standards. Material cracking on the edges and alongside the grooves (creases) can be now excluded. We achived this excellent qulaity by increasing the long fibre content and due to a special surface sizing treatment of the paper. All our stocks have been adapted to these technical developments.

KLUG-CONSERVATION is continually improving the high quality of their paper and board products to ensure that their customers receive the best archival products at economical prices.