- You are here:

- Home

- Products

- Boxes

- Two-piece boxes

- KS 12

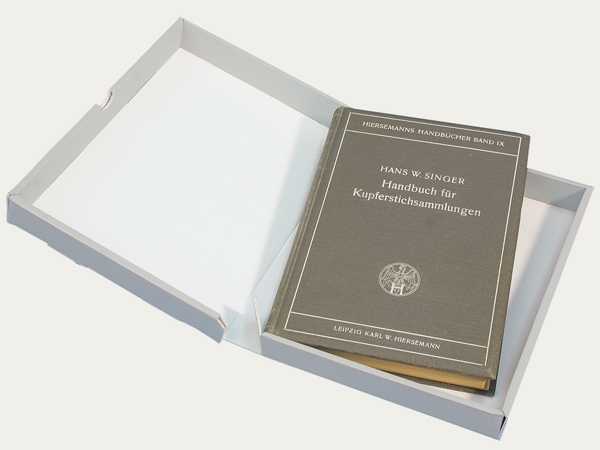

Two-piece boxes KS 12

A two-piece storage box comprising a base and a lid, double-walled on four sides. While closed the box is four-walled all around and thus extremely sturdy. The folding construction ensures smooth interior surfaces. Upon request also available with a drop-front opening.

Please select your desired variant in the table below.Alternative products

Supplementary products

Boxes

Clamshell boxes

Wraparound boxes

Archival boxes

Archival boxes for roll storage

Slipcases, shelf files

Two-piece boxes

» KS 8

» KS 12

» KS 12 – with front window

» KS 12 – with compartments for postcards

» KS 12 – with compartments for photographs

» KS 12 – with compartments for audio cassettes

» KS 16 – Corrugated board

» KS 16 – Boxboard

» KS 16 – with compartments for photographs

» KS 16 – with compartments for slides, negatives and glass plates

» KS 16 – with top window

» KS 16 – with pull-strap and partition inserts

» KS 16 – for video cassettes

» KS 16 – for CD/DVD

» KS 16 – for textiles

» KS 16 – for hats

» KS 16 – for shoes

Folded boxes for film reel storage