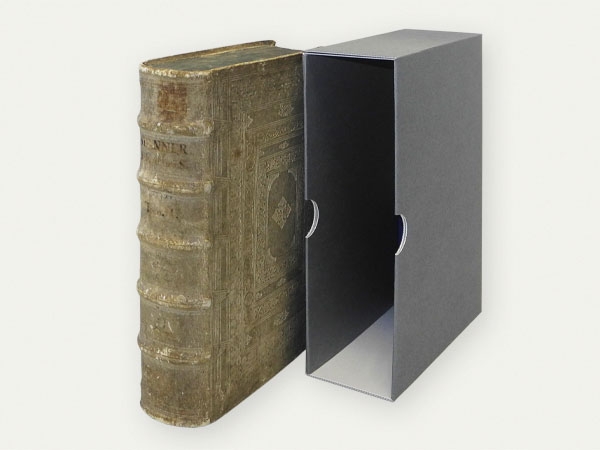

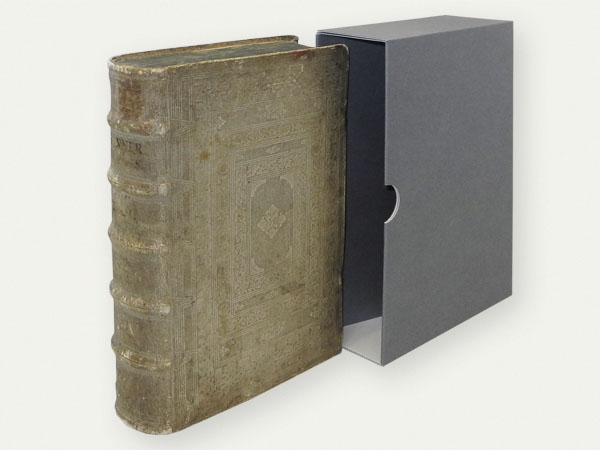

Slipcases, shelf files – KS 23 Slipcase

A classical slipcase, particularly suitable for books, plug-in design, with or without semi-circular grip cutouts. Spine of object visible. Sturdy, inexpensive construction. Upper and lower surfaces made of firmly fitted, double-strength material. Easy to assemble, supplied flat.

The following production tolerances are to be taken into consideration:

Quantity tolerance for paper

± 3% however a minimum of ± 5 sheets per sales unit

Quantity tolerance for board, corrugated board

± 3%

Quantity tolerance for enclosures, folders, boxes

± 8%

Weight (grammage) tolerance

± 7%

Thickness (calliper) tolerance

Paper and board up to 300 gsm ± 10%

Board > 300 gsm ± 5%

Corrugated board ± 8%

Dimensional (size) tolerance for paper and board material

Sizes with plus tolerance max. ± 7 mm

Cutting tolerance 4-sided angular cut ± 2 mm

Dimensional (size) tolerance for corrugated board

Cutting tolerance ± 3 mm

Dimensional tolerance for reeled paper

Roll width ± 5 mm, running metres ± 3%

Dimensional (size) tolerance for enclosures, folders, boxes

Plus tolerance up to 5%

Dimensional (size) tolerance for envelope enclosures

Angle tolerance ± 2 mm, size tolerance ± 3 mm

Dimensional (size) tolerance for tubes

Diameter and tube wall thickness ± 0.3 mm,

lengths ± 10 mm

Perpendicularity tolerance in the case of cuttings with 4-sided angular cut

Angle tolerance 0,6% however a minimum of 3 mm

for 1 m length

Planarity tolerance for corrugated board

Planarity (flatness) tolerance ± 15 mm for 1 m length

Spots (fibre residues and pulp impurities)

Spots with a diameter of less than 0.4 mm are considered insignificant. Mounting board standard specifications stipulate that maximum two spots up to 0.9 mm in diameter each are acceptable per m²

pH tolerance

± 0.5 variation on the pH scale (pH 7.0, pH 6.5 and 7.5 are also permitted)

Deviating tolerances are to be agreed upon separately.

Tolerances

The following production tolerances are to be taken into consideration:

Quantity tolerance for paper

± 3% however a minimum of ± 5 sheets per sales unit

Quantity tolerance for board, corrugated board

± 3%

Quantity tolerance for enclosures, folders, boxes

± 8%

Weight (grammage) tolerance

± 7%

Thickness (calliper) tolerance

Paper and board up to 300 gsm ± 10%

Board > 300 gsm ± 5%

Corrugated board ± 8%

Dimensional (size) tolerance for paper and board material

Sizes with plus tolerance max. ± 7 mm

Cutting tolerance 4-sided angular cut ± 2 mm

Dimensional (size) tolerance for corrugated board

Cutting tolerance ± 3 mm

Dimensional tolerance for reeled paper

Roll width ± 5 mm, running metres ± 3%

Dimensional (size) tolerance for enclosures, folders, boxes

Plus tolerance up to 5%

Dimensional (size) tolerance for envelope enclosures

Angle tolerance ± 2 mm, size tolerance ± 3 mm

Dimensional (size) tolerance for tubes

Diameter and tube wall thickness ± 0.3 mm,

lengths ± 10 mm

Perpendicularity tolerance in the case of cuttings with 4-sided angular cut

Angle tolerance 0,6% however a minimum of 3 mm

for 1 m length

Planarity tolerance for corrugated board

Planarity (flatness) tolerance ± 15 mm for 1 m length

Spots (fibre residues and pulp impurities)

Spots with a diameter of less than 0.4 mm are considered insignificant. Mounting board standard specifications stipulate that maximum two spots up to 0.9 mm in diameter each are acceptable per m²

pH tolerance

± 0.5 variation on the pH scale (pH 7.0, pH 6.5 and 7.5 are also permitted)

Deviating tolerances are to be agreed upon separately.